Formerly known as Bain Poultry Supplies, Ireland’s premier poultry house manufacturer and installer was rebranded as Clea Construction Ltd. in December, 2022. We touched base with Armagh man Joe Renaghan, who spent a-decade-and-a-half as Tommy Bain’s right hand man before taking the reins and continuing with the proud tradition for excellence established by Bain Poultry over the preceding 50 years.

The name Bain Poultry Supplies is synonymous with the manufacture and installation of industry-leading, bespoke poultry houses to hen, chicken, duck and turkey farmers across the island. From its ideal location close to the border, in Keady, County Armagh, the company established an unparalleled reputation for delivering high-quality products – backed by exceptional service – for 50 years under the stewardship of founder Tommy Bain.

Looking after customers in both Northern Ireland and the Republic of Ireland – predominantly close to the border in counties Armagh, Tyrone, Monaghan and Cavan, but also as far field as Cork! – Bain was Ireland’s longest-established poultry house manufacturer and the company earned an outstanding reputation for invariably providing innovative, sturdy, lasting, value-added solutions.

The name may have changed but the same high level of service is bring seamlessly provided by new managing director Joe Renaghan, who is the natural successor to Tommy at the helm of the freshly-titled Clea Construction.

“It’s called Clea Construction now but most people still know us as Bain,” reveals the amiable Keady man. “Tom quit there at the end of last year and I took over. I was working with Tom for 15 great years and learned a lot from him during that time. You couldn’t learn from a better man and my aim is to follow in his footsteps. I’ll be taking the same approach to quality, innovation and customer service as Tom did and it’s been going very well so far, thankfully.”

Like Tom before him, Joe has developed a wonderful camaraderie and working relationship with poultry producers over the years. Supplying cost-effective, modern, convenient and comfortable poultry houses, Clea Construction consistently provides absolute customer (and animal!) satisfaction on each and every installation – be it a large custom-built brand-new unit or a complete top-to-bottom conversion.

“Business has picked up and we’re very busy, so I can’t complain,” said Joe when we recently interrupted his schedule. “Things went quiet enough when the price of everything rose a couple of years ago but it’s picking up again and the orders are coming in.

“There’s great demand for everything. From our perspective, the strong demand for eggs in the North is very positive. That’s keeping us ticking over. In the south, Silverhill Foods are looking for duck houses and Grove Farm are looking for turkey houses. We supply smaller and larger producers and we give them all the same high level of service.”

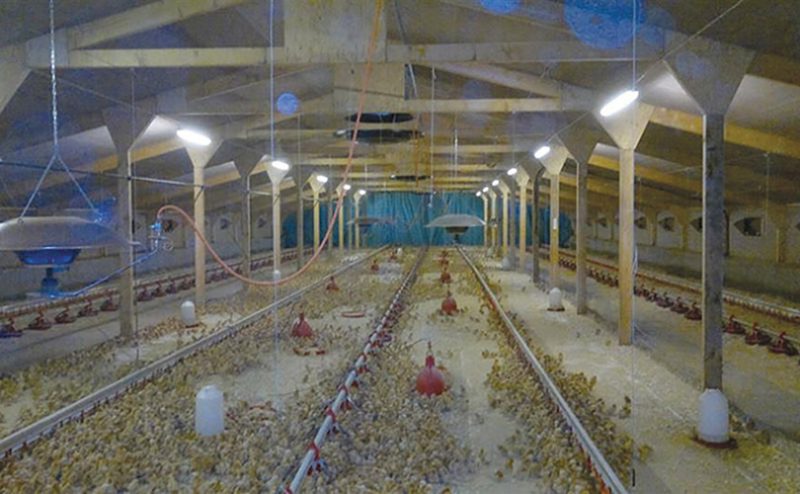

Depending on customer requirements, Joe manufacturers both steel and timber poultry houses, all of which are completed to the highest specifications. All houses – be it broiler, duck or free range – come with a choice of cladding (such as tin, GPR, timber or composite) while second-hand house disassembly and erection is also offered alongside the supply and sale of various poultry related parts and equipment.

All poultry units offer complete comfort and convenience to both birds and producers alike, with nothing left to chance. “The small laying boys like the timber units but the bigger layers and bird houses tend to go for the steel units because they have a larger capacity,” Joe continues. “We manufacture the units to order and install them.

“Generally, we’re doing one large unit every month, which could be for 20,000 birds plus. The standard house is always 300 ft long and they are built in a variety of widths. A lot of them are 300 x 65 ft but they are getting bigger all the time and some boys will even buy two and position them back to back.”

A quality bird house is a major investment, with a fully-kitted-out unit for 32,000 birds currently coming in at around €1.5m, so naturally customers want to get the best return on their money by going with a proven, experienced and skilled manufacturer. Naturally, the skyrocketing cost of overheads has made life more difficult for everybody but Joe is as focused on quality as ever.

“Everything went up by between 20 per cent and 40 per cent,” he reflects. “It was unreal. A house that was €500,000 three years could cost €750,000 today. Prices have gone through the roof, unfortunately. But people still need chickens and eggs and producers still need quality houses for their birds.

“For whatever reason, there’s a better margin on eggs in the North at the minute and that’s been a boost. They are very popular and a lot of them are going to England. We move with the market. Things were very quiet eight to ten months ago when eggs went down in price. But everybody is crying out for eggs now and there’s great demand for them, especially in the North, where the market and the price seems to be dictated by England. They weren’t filling their houses in England and supply dropped, and a lot of eggs from Northern Ireland are going over to England now. When the houses in England fill up again, there could be a lull here; it’s hard to know what way things will go…”

To complement the manufacture and sale of new units, there’s always strong demand for refurbished and converted poultry houses. “We tidy up and convert a lot of old houses,” Joe confirms. “At the moment, we’re converting an old Moy Park unit into a laying house in Belfast. These units would be completely gutted, with a new roof and new walls shuttered. They are completely transformed.”

Clea Construction generates full-time employment for a crew of six and brings in additional subcontractors to erect steel. As Joe points out, with standards and specifications rising all the time, the result is more comfortable but more expensive accommodation for the birds:

“The food companies are always pushing for a higher standard of house with higher specs. For example, they want to let more daylight in now and that adds to the expense. The higher the spec, the higher the price. Including windows to let light in is a big extra cost and that is passed on to the farmer. All new steel houses now have windows and increased insulation and we manufacture the units to the exact spec that’s set out for us.

“These are tough times for producers because their costs have risen across the board – electricity, heat, equipment, etc. – but the price of the poultry and eggs probably hasn’t risen in line with that. The price of materials is out of our hands – but quality isn’t and we make sure every unit we make and install is exactly as requested and of superior quality.”

Bain Poultry Services / Clea Construction’s track record for delivering quality poultry houses is second to none and even in this times of uncertainty customers can rest assured that Joe fully intends to build upon and enhance that outstanding legacy for excellence.

Clea Construction Ltd. (formerly Bain Poultry Supplies),

57A Clea Road,

Keady,

County Armagh.

Tel: 0044 77 =25918941

Email: [email protected]

First published in Irish Tractor & Agri magazine Vol 11 No 4, August/September 2023

Bain Poultry Supplies, Clea Construction